Heavy equipment is essential in industries like construction, mining, and agriculture, enabling large-scale operations and infrastructure development. However, these powerful machines also pose significant safety risks to operators and workers, as well as environmental challenges due to emissions, fuel consumption, and potential hazards like spills or structural failures. To mitigate these risks, manufacturers have introduced advanced safety technologies, including collision avoidance systems, telematics, and emergency stop mechanisms. This article explores these cutting-edge innovations, highlighting how they enhance worker safety, improve operational efficiency, and reduce environmental impact, ensuring a safer and more sustainable future for heavy machinery operations.

Table of Contents

1. Proximity Detection Systems

Proximity Detection Systems (PDS) are advanced safety solutions designed to reduce accidents in heavy equipment operations by creating an invisible safety zone around machinery. Using electromagnetic fields and sensor technologies, these systems continuously monitor the surrounding area, alerting operators and nearby workers of potential hazards. In some cases, they can automatically slow or stop machinery to prevent collisions. By enhancing situational awareness—especially in blind spots or confined spaces—PDS significantly reduces the risk of injuries and fatalities, making work environments safer and more controlled.

Beyond worker safety, PDS contributes to operational efficiency and environmental protection. By preventing unnecessary collisions, these systems help minimize damage to equipment, lowering maintenance costs and reducing the environmental footprint of repairs. Integrated with GPS and real-time tracking, PDS enables optimized traffic management and data-driven safety improvements, allowing companies to identify high-risk areas and refine safety protocols. As technology advances, these systems are evolving to offer even greater precision and automation.

2. Collision Avoidance Systems

Collision avoidance systems have become a critical safety feature in modern heavy equipment, leveraging sensors, cameras, radar, and intelligent algorithms to detect obstacles and alert operators in real-time. These systems significantly reduce the risk of accidents, particularly in crowded or low-visibility environments, by enhancing situational awareness and identifying both stationary and moving hazards. Some advanced models, such as Wabtec’s Collision Avoidance System Generation 3, can even autonomously slow down or stop machinery to prevent collisions, improving worker safety and reducing fatalities in industrial settings.

Beyond safety, these systems contribute to environmental protection and operational efficiency. By preventing unintended impacts on natural barriers, they help preserve surrounding ecosystems, supporting sustainable construction and mining practices. Additionally, they minimize equipment damage and downtime, reducing maintenance costs. Scalable and adaptable, many systems integrate with other safety technologies, such as GPS tracking and fleet management, ensuring a comprehensive approach to accident prevention in heavy equipment operations.

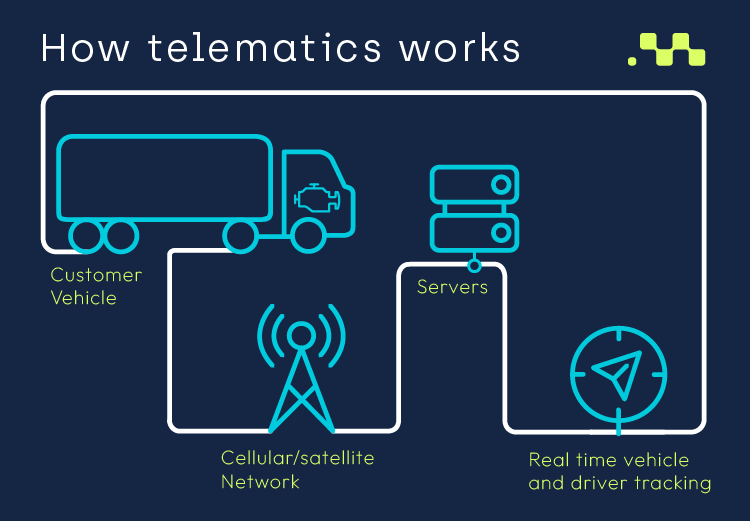

3. Telematics and Real-Time Monitoring

Telematics and real-time monitoring have transformed heavy equipment safety and operational efficiency by providing real-time data on machine performance, location, and operator behavior. This technology enhances worker safety by identifying hazardous operating patterns, monitoring driver actions like speeding or sudden braking, and enabling geofencing to alert operators when equipment enters restricted areas. Additionally, collision detection systems and emergency alerts help prevent accidents, while predictive maintenance minimizes unexpected failures, reducing downtime and safety risks.

Beyond safety, telematics plays a crucial role in environmental sustainability by optimizing fuel consumption, reducing unnecessary idling, and lowering emissions to meet regulatory standards. By improving equipment utilization and extending machinery lifespan through proactive maintenance, companies can reduce waste and minimize their environmental footprint. With the telematics market projected to surpass $37 billion by 2030, its growing adoption underscores its value in promoting safer, more efficient, and eco-friendly heavy equipment operations.

4. Operator Assistance Technology

Operator assistance technology is transforming heavy equipment operations by enhancing precision, reducing operator fatigue, and improving overall safety. Automated controls and real-time monitoring systems help prevent accidents by alerting operators to potential hazards, such as excessive loads, unsafe speeds, or unstable terrain. Features like automated grade control in excavators and load-sensing technology ensure safer and more accurate operations, minimizing human error and workplace injuries. These advancements significantly reduce risks such as falls, collisions, and electrocution, creating a safer work environment for operators and surrounding personnel.

Beyond safety, these technologies contribute to environmental sustainability and cost efficiency. By reducing material wastage and optimizing operations, they help preserve natural resources while lowering fuel consumption and emissions. Additionally, early detection of equipment issues prevents costly repairs, improving long-term profitability. Although the initial investment may be high, studies show that accident-related costs can be significantly reduced, making these innovations a valuable addition to modern heavy equipment fleets.

5. Emergency Stop Systems

Modern heavy equipment integrates emergency stop systems and engine shutdown packages, providing rapid response to hazardous situations and enhancing worker safety, equipment protection, and environmental security. Emergency stop buttons, designed for immediate recognition with red and yellow markings, halt operations instantly upon activation. Meanwhile, engine shutdown packages automatically cease fuel flow within seconds when fire suppression systems engage, preventing escalation of fires and potential damage.

These systems are critical for worker safety, enabling swift intervention to prevent accidents, particularly in high-speed automation settings. They also protect equipment, reducing costly repairs by quickly stopping malfunctions. Additionally, they offer environmental protection, limiting contamination from hydraulic fluid or fuel leaks. Compliant with international standards such as ISO 13850 and IEC 60947-5-5, these safety features underscore manufacturers’ commitment to reducing risks and maintaining operational integrity in industrial environments.

6. Enhanced Visibility Solutions

Modern heavy equipment incorporates advanced visibility systems to enhance operator awareness and improve safety on job sites. Key innovations include 360-degree camera systems, which use multiple cameras to create a real-time panoramic view of the machine’s surroundings, displayed in the operator’s cabin. This technology eliminates blind spots, enhances maneuverability in confined spaces, and protects nearby workers. Additionally, blind spot detection systems equipped with sensors or radar technology, such as Stoneridge’s SideEye, alert operators to hidden obstacles or pedestrians, further reducing accident risks.

LED lighting advancements also play a vital role, providing powerful illumination during low-light operations to extend safe working hours. These visibility solutions not only enhance worker safety by preventing collisions but also offer environmental benefits by helping operators avoid unintended contact with natural habitats. As industry regulations, like the EU General Safety Regulation, evolve, these technologies are becoming essential safety standards in modern heavy machinery.

7. Biodegradable Hydraulic Fluids

Biodegradable hydraulic fluids represent a significant advancement in the heavy equipment industry, offering both environmental protection and worker safety. Derived from renewable resources such as vegetable oils and synthetic esters, these eco-friendly fluids degrade rapidly—over 60% within 28 days—minimizing long-term environmental harm. Their low toxicity makes them safer for ecosystems, particularly in sensitive areas like agricultural lands and marine environments. Additionally, these fluids contribute to worker safety, reducing health risks due to lower toxicity and offering improved fire safety through higher flash points.

Performance-wise, biodegradable hydraulic fluids deliver excellent lubrication, wear protection, and oxidation stability, often matching or exceeding conventional alternatives. Their superior lubrication properties help extend equipment lifespan and reduce maintenance costs, promoting operational efficiency. Commonly used in agriculture, forestry, construction, mining, and marine operations, these fluids are particularly valuable in environmentally protected zones. Adopting biodegradable hydraulic fluids reflects a commitment to sustainability, meeting modern environmental regulations while protecting both people and ecosystems.

8. Rollover Protection Systems (ROPS) and Falling Object Protection Systems (FOPS)

Rollover Protection Systems (ROPS) are engineered structures designed to shield operators during vehicle rollovers by maintaining a survivable space within a reinforced frame or cabin. Common in tractors, excavators, and construction vehicles, ROPS are available in 2-post, 4-post, or enclosed cabin designs, meeting stringent standards set by OSHA, ISO, and OECD. These systems undergo rigorous strength and energy absorption testing to ensure operator protection in high-risk environments.

Falling Object Protection Systems (FOPS) protect operators from falling debris, crucial in sectors like mining, forestry, and construction. Available in two protection levels—Level 1 for small objects and Level 2 for larger debris—FOPS are often integrated with ROPS for comprehensive protection. Effective use of ROPS and FOPS not only prevents injuries and fatalities but also boosts operator confidence and productivity. As from the Spring of 2025, new regulations will mandate Level 2 FOPS and ROPS cabins for machinery exceeding 4.5 tons, highlighting their importance in ensuring workplace safety

The Path to Safer and Greener Operations

The integration of advanced safety technologies in heavy equipment highlights the industry’s commitment to protecting both workers and the environment. Innovations such as collision avoidance systems, telematics, and emergency stop mechanisms not only mitigate risks but also improve operational efficiency and sustainability. As industries increasingly adopt these technologies, they contribute to safer worksites and reduced environmental impact. Embracing these advancements is more than a regulatory necessity—it is a strategic investment in long-term safety and ecological responsibility. By prioritizing innovation, companies pave the way for a future where safety and sustainability go hand in hand.

Ningo, founder of Big Machines Today, is a passionate writer and content creator specializing in heavy-duty machinery. Focused on delivering industry insights and trends, Ningo crafts engaging content for professionals. Open to free collaborations on blogs or social media articles, Ningo invites you to connect and explore the Big Machines Today Blog for valuable updates.

I really enjoyed this post educational and interesting. Thanks for sharing your knowledge with your readers.